How we Recycle

At Recolight, we meet our targets entirely by organising the collection and recycling of waste lighting. That means we offer a free collection and recycling service – an invaluable solution for our Members, their customers, and end users.

At Recolight, we meet our targets entirely by organising the collection and recycling of waste lighting. That means we offer a free collection and recycling service – an invaluable solution for our Members, their customers, and end users.

Recolight use Approved Authorised Treatment Facilities to recycle waste. This ensures that the waste is treated responsibly, maximising the amount of recycling that can achieved and its impact on the environment.

We have full duty of care traceability – we know exactly where the waste we collect has come from, and how and where it gets recycled.

Recolight Members recognise that WEEE compliance is about more than just ticking a box and are actively committed to protecting the environment.

Downloads

Working with recycling and logistic operators

- Our recycling and logistics operators are sourced to conform to the relevant statutory requirements of the Regulations and Standards.

- Our purchasing and tendering process specifies the criteria with which potential Operators will have to comply. We seek Operators with the highest quality standards

- Recolight also organise regular, comprehensive audits of our contracted operators to verify compliance with the relevant UK Regulations and Recolight’s own criteria.

- Recolight finance the costs of collection and recycling both from many Local Authority Designated Collection Facilities (Household Waste Recycling Centres) and also Commercial Collection Points.

- Commercial collection points apply to join our collection network and agree to operate according to our standard terms which include health and safety.

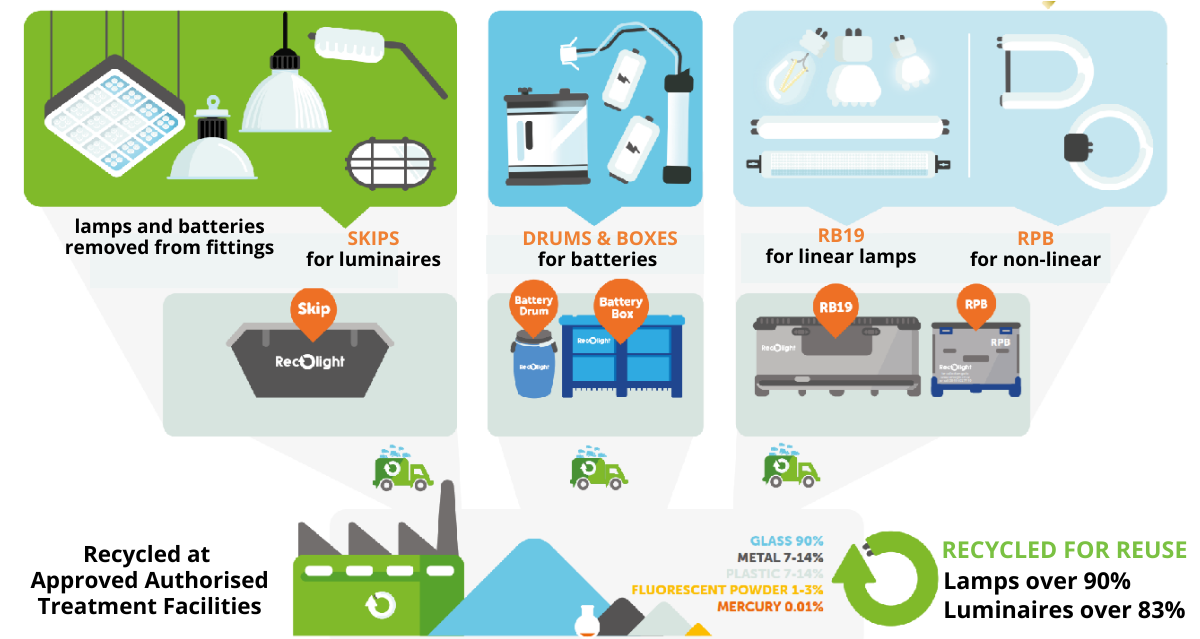

The Recolight recycling process

Recycling luminaires with traditional and LED sources

Most luminaires, regardless of the technology inside, are treated in the same way as most other non-hazardous small mixed WEEE. This includes luminaires based around traditional lamp technologies such as fluorescent and High Intensity Discharge (HID) lamps.

Assuming the luminaire is not suitable for refurbishment and re-use, the objective of treatment is to separate the device into its’ constituent materials (plastics, metals, etc.).

Lamp recycling process

Lamp recyclers use different recycling technologies although the principles are all broadly similar.

- Waste lamps are fed into the recycling plant under negative air pressure.

- The lamps are then crushed using a mechanical process, and the negative air pressure ensures that the mercury vapour released is captured in activated carbon filters and not vented to the environment.

- The crushed materials then pass through a range of different systems designed to separate them from each other.

- The output fractions are collected in separate containers, and then sent for further recovery.

LED lamp recycling

LED lamps can be recycled with other WEEE as they do not contain mercury and are more similar in nature to other WEEE than to fluorescent lamps.

When co-collected with fluorescent lamps there is a risk of mercury contamination. This is because unavoidable breakages in general containers will cause some fugitive emissions. Therefor they must be treated as mercury bearing lamps.

The diversity of LEDs

The diversity and rapidly evolving nature of design and construction of LEDs presents additional challenges to their recycling. LEDs contain rare earths, but there is no value in attempting to recover these as they exist in each lamp in such minute quantities.

Retrofit LED tubes can cause a problem for some lamp recycling equipment because they often contain lots of very strong rigid materials, they don’t break up in the same way as a normal glass lamp in the treatment machinery.

They can be separated and manually dismantled like many luminaires, or they can be sent to a general WEEE processing plant.

Due to of the vast range of designs of LED lamps, and the wide range of materials used in their construction, the recovery of material for LED lamps can be materially less than those for fluorescent.

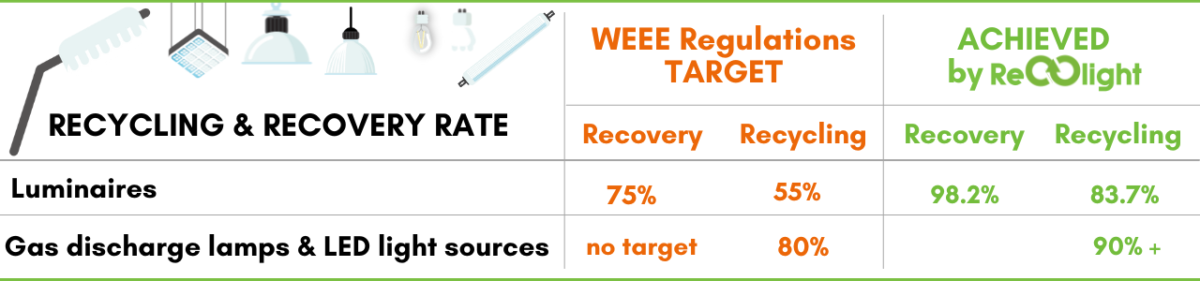

Recycling and Recovery rate of lamps and luminaires

The WEEE regulations set a target for recovery and recycling that must be achieved by an Approved Authorised Treatment Facility (AATF). The recycling rate achieved by Recolight’s contracted AATFs for lighting equipment and lamps exceeds the targets set.

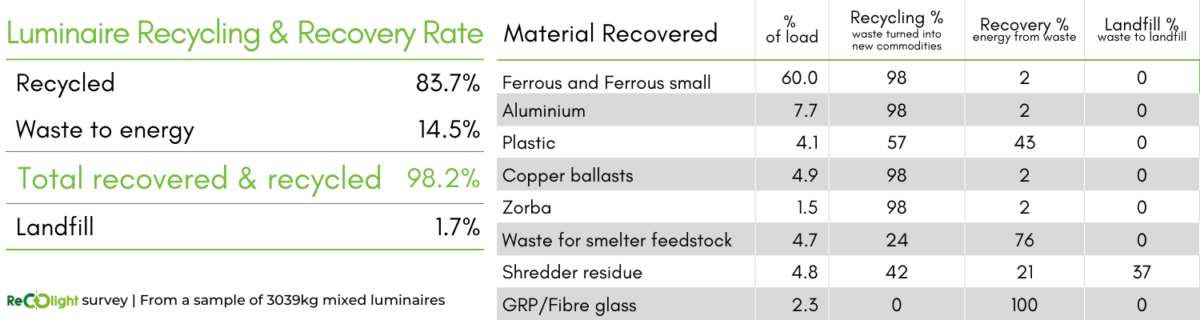

Luminaire recycling & recovery rate

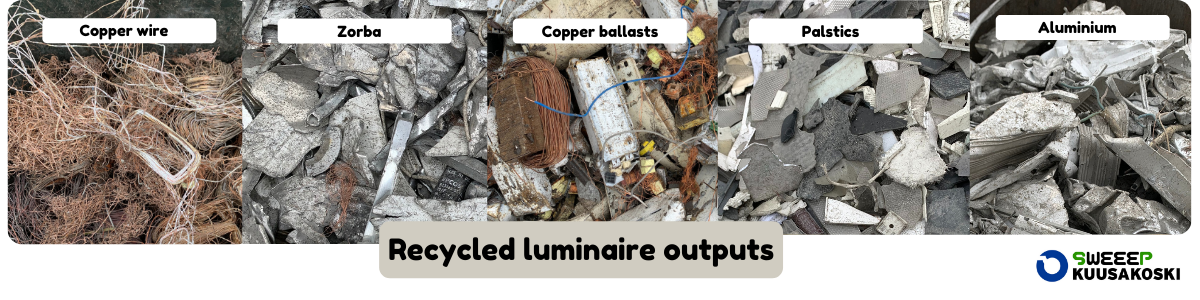

Recolight commissioned SWEEEP Kuusakoski to assess the recyclability of waste luminaires. A sample of three tonnes of mixed luminaires were treated to establish the recycling and recovery rate of materials.

It is encouraging that 83% of material recovered from our sample could be recycled. But disappointing that over 14% didn’t make the grade, and was sent for waste to energy; a process that produces carbon emissions. It’s pleasing to note that only 2% went to landfill because it was neither recyclable nor could be used to create energy.

The bulk of material used for waste to energy was plastics. It seems likely that circular economy legislation and standards may require or incentivise manufacturers to include a proportion of plastic from recycled sources. Recolight would like to see more manufacturers using plastic derived from recycling in the manufacture of new fittings in preference to only using new plastic.

Recycling rate for lamps

The recycling target set by the WEEE Regulations for gas discharge and LED lamps is 80%. The Recolight recycling processes achieve over 90%.

The principle materials recovered are :

- Glass

- Aluminium and circuit boards

- Phosphor powders containing rare earths and mercury

- Plastics

The materials recovered from the various recyclers’ processes are used in many ways.

- Aggregate in road construction is the most common use of lamp waste.

- The metal and plastics are collected together and sent to specialist recyclers who separate the various plastic and metal types from each other.

- Each is then melted down and re-used as raw materials for manufacture of new plastic and metal products of almost any kind.

- It is technically feasible to recover the rare earths from the lamp phosphor powders, and we are undertaking further research into this through our European trade association, EucoLight.

The mercury arises in the lamp vapour released when the lamp is broken and in the phosphor powders. Depending on the concentration in the powders, high temperature distillation of the powder may be necessary to separate it out. When purified to the right level, it may be used as a raw material to make new lamps or in other industrial processes.

The future of LED luminaire recycling

The convergence of lamps and luminaires into LED luminaires will mean one larger unit will be treated in the future. Investment in new treatment technology must take careful note of these developments in the lighting market. The rate for separately collected luminaires in the UK is currently very low compared to the lamp recycling rate.