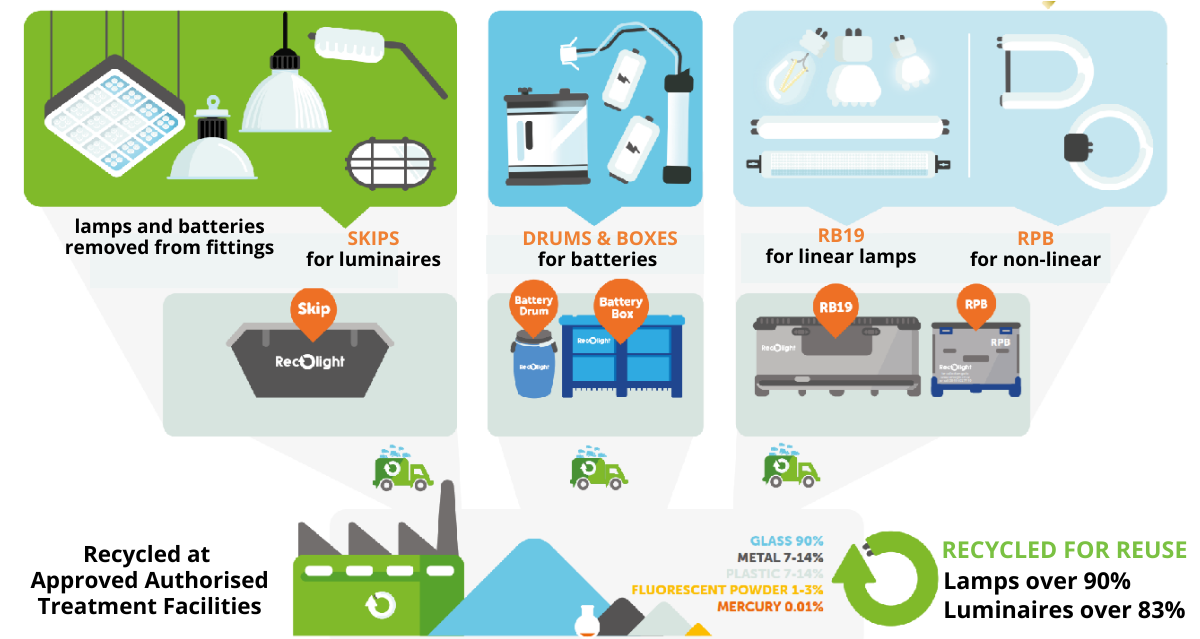

HOW WE RECYCLE

At Recolight, we meet our targets entirely by organising the collection and recycling of waste lighting. That means we offer a free collection and recycling service – an invaluable solution for our Members, their customers, and end users.

At Recolight, we meet our targets entirely by organising the collection and recycling of waste lighting. That means we offer a free collection and recycling service – an invaluable solution for our Members, their customers, and end users.

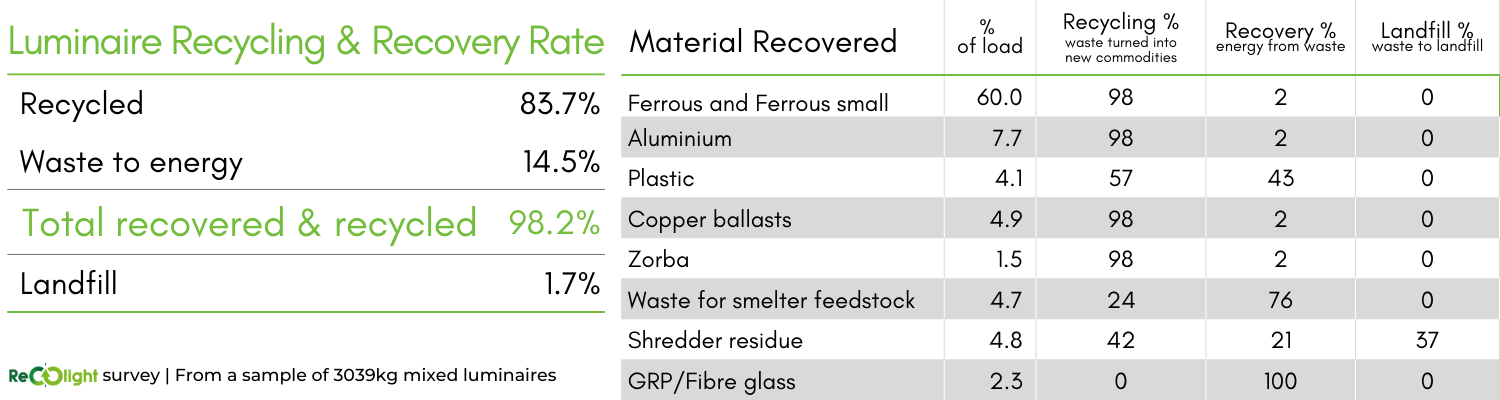

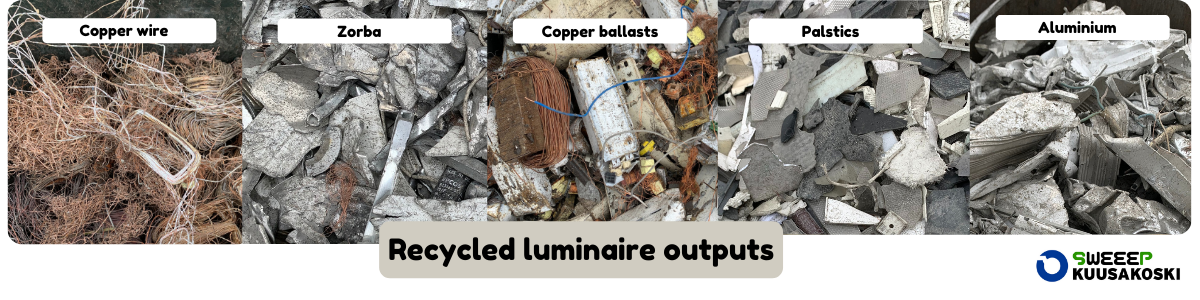

Recolight use Approved Authorised Treatment Facilities to recycle waste. This ensures that the waste is treated responsibly, maximising the amount of recycling that can achieved and its impact on the environment.

We have full duty of care traceability – we know exactly where the waste we collect has come from, and how and where it gets recycled.

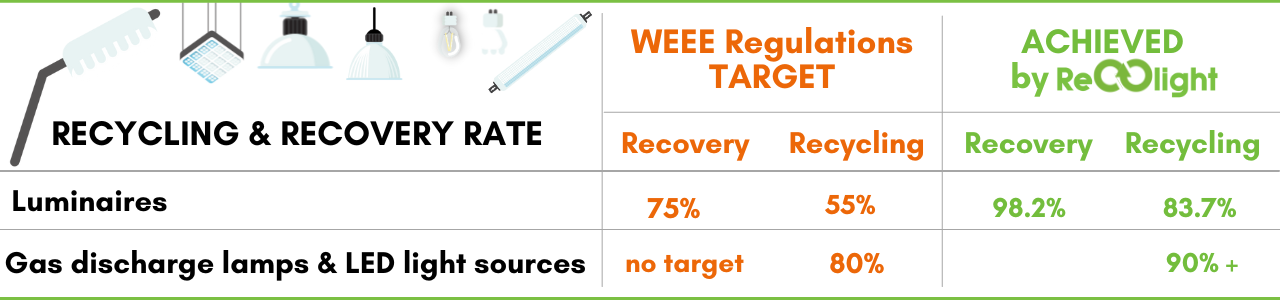

Recolight Members recognise that WEEE compliance is about more than just ticking a box and are actively committed to protecting the environment.