Fagerhult has upgraded 2,700 luminaires for reuse in an office building in Stockholm.

Greenhouse is a modern workspace of up to 20,000 square meters in an old brick property. The goal of the project was to modernise it in a sustainable way, while still preserving the value of its history.

As well as the luminaires, the developers kept and reused the interior ceilings, glass partitions, and doors.

Fagerhult got involved at an early stage of the project to convert and transform the old luminaires into modern presence- and daylight-controlled LED luminaires.

‘By refurbishing the luminaires, we were able to achieve significant environmental and economic savings,’ said Kjell Wallin of Fagerhult.

‘We could keep the electrical installations, avoid new wiring and making new holes in the ceiling. To future-proof the building, we also installed our plug-and-play lighting control system, Organic Response, in every luminaire. ‘Incorporating a control system, ensures a future-proof solution since it creates the possibility to add on services and integrations to a Building Management system, if needed.’

Transporting the luminaires from Stockholm to Fagerhult’s factory and back would entail significant greenhouse gas emissions and undo the environmental benefits of refurbishing the luminaires, so it was decided to do the refurbishment work on site.

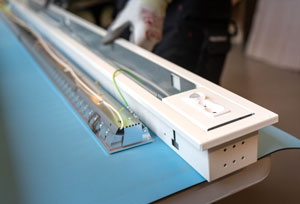

A full-scale production line was created at Greenhouse where Fagerhult planned and organised all the set-up in collaboration with the on-site electricians for an efficient workflow.

All the old luminaries were disassembled, the luminaire body was reused, and all excess material were sorted into different fractions and recycled. The old light sources were replaced with LEDs and integrated Organic Response sensors to save energy. Everything was customised to fit into the old luminaire body.

‘This project required a lot of creative solutions and quick thinking,’ said Wallin. ‘For example, while transporting the luminaires between different floors we needed to develop special cages since the elevators were too narrow to fit a forklift. On site we found old bread cages that fit into the elevators, these were reconstructed to safely transport the luminaires’.

All new luminaire parts were tested at the company’s laboratory according to the standards. After a luminaire had been rebuilt, complementary and final tests were also carried out on site.

The company estimates that by reusing the existing luminaires it has saved 7.1 tons of material and 2,297 megawatt-hours of energy over a 20-year lifecycle.

• Diary date: Circular Lighting Live 2024, Recolight’s flagship conference and exhibition, takes place on Wednesday 9 October 2024 at the Royal College of Physicians in London. Free to specifiers, Circular Lighting Live 2024 will feature leading experts, specifiers and policy makers who will share their insights into forthcoming standards and legislation, emerging technologies and new business models. More info: www.circularlighting.live