CIRCULAR ECONOMY & SUSTAINABILITY

“Sustainability really matters. More than ever. We can all see the effects of the changing climate around us. Longer and hotter heatwaves, more flooding, more wildfires, and increasingly devastating storms and other extreme weather events.

The Recolight response is twofold: Firstly, we try to put our own house in order. We put in place policies and strategies to reduce our own carbon footprint, to improve the circularity of what we do, and to encourage our suppliers of transport and recycling services to do likewise.

And secondly, we use our role as one of the UK’s leading WEEE schemes, to encourage others in both the lighting and waste sectors to also adopt more circular economy principles and to reduce carbon emissions.

This document explains what we are doing to meet those two objectives.

Pleasingly, the strategies are bearing fruit. There is still a great deal that we must all do, both within the lighting sector and beyond but it is good to recognise that change is in the air.”

Nigel Harvey, Recolight CEO.

Lighting & The Circular Economy

Transformation to a Circular Economy is an essential requirement for manufacturing businesses. This will become ever more important as demand for resources rises, energy costs increase, and the need to decarbonise accelerates.

- Resource depletion will begin to drive up the cost of raw materials, leading to more use of recycled materials.

- A route for fixtures to enjoy further lives after the original installation is a natural conclusion for Circular Economy adoption.

- Services are available to facilitate the reuse and repair of fittings. Remanufacturers have indicated they will provide warranties and certification of reused product.

- There is an emerging opportunity for maintenance and manufacturing companies to offer re-manufacture or reconditioning services.

- Specifiers have a crucial role to play in educating end users about the importance of using products which embody Circular Economy principles.

- Future reforms to the WEEE Regulations will incentivise reuse, and circular business models. Defra is considering setting separate targets for reuse

ADVANCING THE CIRCULAR ECONOMY

Expanding Industry Engagement: New Webinars and Conferences

Recolight webinars have been attended by lighting manufacturers, users, designers, specifiers, distributors, and contractors; the whole supply chain.

Over 2024 and 2025, the webinar series has included topics such as:

Understanding environmental metrics

Complying with future eco design regulations

Designing lighting for disassembly and reuse

Procuring sustainable lighting: A specifier’s guide

The UK’s largest event dedicated to sustainable lighting. Established by Ray Molony, and Recolight in 2022, the event has become a vital touchpoint on the industry’s journey to a low carbon, circular economy. The conference brings together leading experts, specifiers and policy makers to share their insights into forthcoming standards and legislation, emerging technologies and new business models.

In 2024, Recolight launched the Net Zero Lighting Conference, the UK’s first dedicated event focused exclusively on achieving net zero within the lighting industry. The conferences underlined the urgency of action and the vital role of lighting in the broader climate agenda. As interest grows in regulatory frameworks and corporate sustainability goals, Recolight is committed to helping to keep net zero a cornerstone of the sector’s sustainability efforts.

DRIVING PRODUCT SUSTAINABILITY

Recolight continue to demonstrate sector leadership through an expanded programme of Circular Economy webinars and conferences. These events play a critical role in equipping the lighting industry with the knowledge and tools required to accelerate the shift to sustainable practices.

Attendance at these events underlines the growing appetite across the supply chain to understand and apply circular economy principles. The webinars also serve as a practical learning platform, helping manufacturers navigate increasingly complex sustainability requirements and certifications.

These initiatives support Recolight’s strategic mission to foster collaboration, raise industry standards, and accelerate the transformation to a circular and low-carbon lighting sector.

Recolight are encouraged to see the lighting industry taking steps to become more sustainable. It is a given that the industry produce light sources that are now very energy efficient. The understanding of how our industry can really become sustainable is evolving and that needs change right across the supply chain.

LCA and EPD Services

In 2024, Recolight significantly enhanced its offering to support the lighting industry’s journey towards sustainable product innovation with the launch its Life Cycle Assessment (LCA) service. This service offers training and support to lighting manufacturers on the LCA methodology with particular emphasis on its use for Environmental Product Declarations (EPDs). LCAs enable manufacturers to understand the environmental performance of their products, enabling sustainable innovation.

Recolight provide training in LCAs via webinars open to all including manufacturers, designers and other lighting professionals, but also in more detailed format as day-long in-person workshops. Workshops are designed for manufacturers looking to learn the LCA methodology and the implementation of an EPD strategy. For those manufacturers looking to take a comprehensive approach to EPDs, Recolight provide support services, offering licensing for the One Click LCA software platform, the relevant onboarding training and ongoing, on-demand support.

Complementing this is Recolight’s One-Off EPD service, which provides lighting manufacturers with an accessible and cost-effective pathway to obtaining their first EPD. Recognising that traditional EPD development can be resource-heavy, Recolight’s One-Off service provides a stepping stone into the EPD journey at a competitive price.

Together, these services remove barriers for lighting manufacturers and specifiers aiming to quantify and communicate their sustainability credentials and help prepare the industry for future legislative and procurement requirements.

Lighting remanufacturing workshops

Recolight’s one day Remanufacturing Lighting Products workshop equips lighting manufacturers to establish or outsource a remanufacturing process.

Led by Simon Fisher, the session covers LED retrofit design, compliance testing, and applying the BS8887:221 standard.

Delegates explore assessing used luminaires, upgrade options, warranties, liabilities, and measuring environmental benefits such as carbon savings. The workshop supports circular economy goals by showing how reuse can cut embodied carbon.

Designed for professionals across technical, compliance, and sustainability roles, it uses a roundtable format with case studies, common pitfalls, and a Q&A. An in-house version is also available.

RAISING AWARENESS ACROSS THE INDUSTRY

CIRCULAR LIGHTING REPORT

Launched in June 2022, the Circular Lighting Report is Recolight’s digital platform for thought leadership, insight, and industry news focused on sustainability in the lighting sector. Curated and edited by Ray Molony, the platform hosts articles, interviews, and opinion pieces from leading experts.

Covering themes like product design, remanufacture, eco-design policy, carbon reduction and other sustainability initiatives, Circular Lighting Report is widely regarded as an essential resource for professionals across the supply chain. The platform averages 30,000 impressions each month on LinkedIn, underscoring its growing influence and reach.

The report reinforces the organisation’s central role in driving sustainable transformation across the sector.

FACILITATING THE CIRCULAR SUPPLY CHAIN

Beyond the first life of luminaires

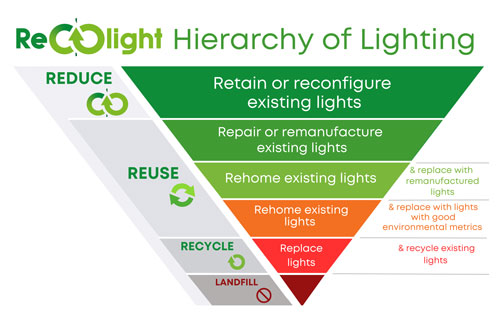

The need to no longer see luminaires as a single life product has been widely discussed in the Recolight Webinar series. At Recolight, we recycle, but as we move towards a Circular Economy model, recycling is not always the best solution.

Recolight has identified opportunities for the lighting industry to avoid unnecessary waste and to help achieve this, Recolight has established the Recolight Reuse Hub:

REUSE HUB

Recolight’s Reuse Hub is a platform that connects donors of lighting products with potential recipients. Launched as a proactive step toward scaling circular practices, the Reuse Hub includes two key services:

Used Fittings: Recolight collects and redistributes data on used fittings removed from refurbishment projects, linking them to remanufacturers who can repair or upgrade and re-certify them for further use.

Surplus New Stock: Recolight facilitates the donation of surplus or unsold new lighting stock from manufacturers and distributors to organisations that can deploy it in new applications, avoiding unnecessary recycling or waste.

This integrated hub simplifies the reuse process and gives manufacturers, contractors, and specifiers the confidence to embrace circular models. By making reuse as seamless as recycling, Recolight continues to shift the mindset of the industry toward long-term sustainability.

Protecting the environment

The reuse or disposal of end-of-life equipment should be an integral part of all LED luminaire replacement projects. Not just for legislative compliance, but also to meet the sustainability and corporate social responsibility requirements.

To increase the reuse and recycling rates specifiers should insist that producers take responsibility for recycling of the waste luminaires that arise. An even better environmental outcome is for the luminaires to be LED retrofitted in situ.

End users want to know more than just how the lighting will be reused or recycled. Increasingly, they are asking producers for the percentage of components and complete fittings that can be recycled, and the percentage of recycled material used in the manufacture.

Recycling

Where reuse is not possible, for technical or commercial reasons, recycling is the next best option.

The waste hierarchy quite rightly puts recycling below prevention, repair, and reuse. To drive improved sustainability in the lighting sector, we must get much better at applying the waste hierarchy. That means prioritising repair and reuse above recycling. Historically in our industry, we have regarded getting waste recycled as good enough. We need to change that mentality.

Lamp recycling rates in the UK have grown faster than any other waste electrical equipment category; from 19% in 2008, to 43.1% in 2020, and 68% in 2023. The lighting industry is unique in taking such an effective, sector specific approach to waste and recycling. Electrical contractors, wholesalers and lighting manufacturers can be proud of this recycling record and contribution to sustainability.

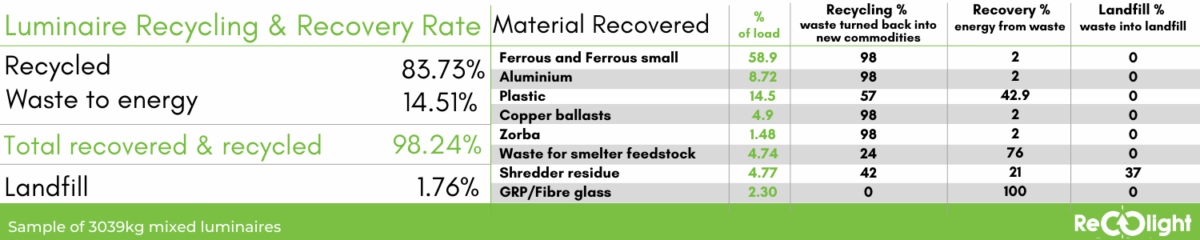

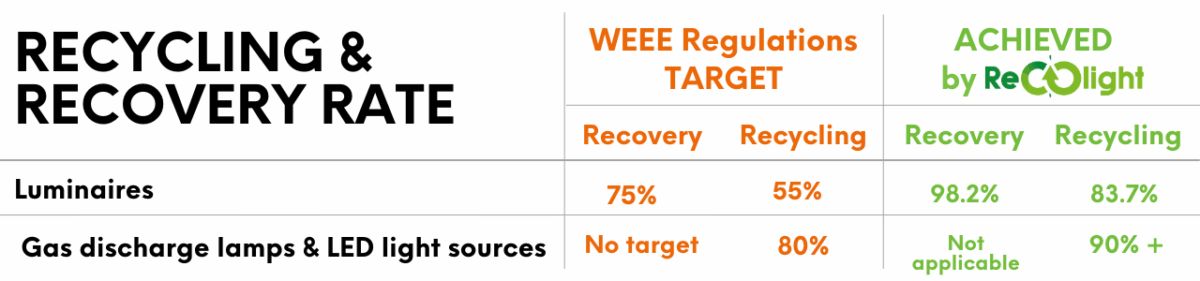

Recolight’s recycling and recovery rate

The WEEE regulations set a target for recovery and recycling that must be achieved by an Approved Authorised Treatment Facility (AATF).

The recycling rate achieved by Recolight’s contracted recyclers comfortably exceed the recycling and recovery requirements set in the WEEE regulations:

Recycling rate: Percentage of material recovered during the recycling process.

Recovery rate: Percentage of material recovered including energy recovery during the recycling process.

Luminaire recycling and recovery rate

The breakdown of raw materials recovered after treatment of a typical load of luminaires has been independently assessed: