A BREAKTHROUGH in laser research could lead to lighter optics for luminaires and minimise the use of materials.

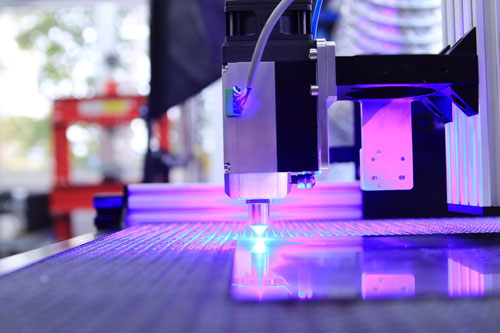

The Fraunhofer Institute in Munich says it is making significant progress by combining hybrid materials with laser surface radiation.

Its studies are being driven by an industry trend toward lightweight construction and increased functionality.

In the Form-LIGHT project, the Fraunhofer Institute’s laser technology department is focusing on developing a micro-mouldable plastic and light metal hybrid material composite for a Class A surface.

Using laser radiation on the surface, the researchers structure the magnesium and aluminium to optimise performance and then turn the new material into useful components for the lighting industry through injection moulding.

In addition, they vaporise the reflector with a special reflective layer. In doing so, they meet the requirements of LED technology by combining metallic die-cast components with good thermal conductivity and the high surface quality of injection moulded components.

Specifically the scientists are researching what are termed ‘sandwich composites’ made from continuous-fibre-reinforced face sheets and a honeycomb core to allow for maximum lightweight construction performance and minimal material usage in the production of large area structural parts.

The TS-Moulding process – developed and patented by the Fraunhofer Institute for Microstructure of Materials and Systems –facilitates the production of complex-shaped, continuous-fibre-reinforced sandwich structures.

In combination with thermoplastic injection moulding or extrusion, these can then in turn be processed into ready-to-use structural parts for luminaires.

By combining these processes, fibre composite lightweight construction parts with thermoplastic matrix polymers can be custom-produced in high volumes.

A breakthrough in hybrid and lasered material is significant as it could allow the lighting industry to reduce its use of PMMA, or poly methyl methacrylate, an engineering plastic also known as acrylic or acrylic glass.

Earlier this year, a Swiss firm unveiled a series of sustainable microprismatics for luminaire optics made from 90 per cent recycled PMMA.

Zurich-based Jungbecker says its Greenline will make an important contribution to sustainability in the lighting industry.

• Recolight offers special one-day training workshops on ‘Lighting product design for a Circular Economy’. Hosted by industrial designer Simon Fisher of F Mark, the CPD-accredited event explores the design criteria, regulations and standards to help lighting manufacturers apply and demonstrate circular economy principles in product development. More HERE.