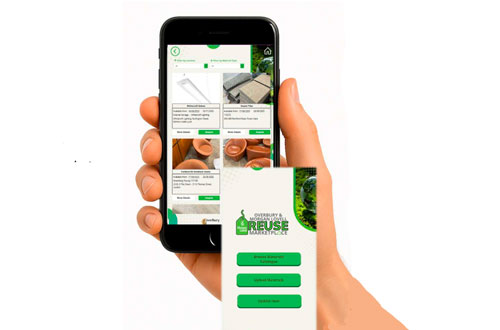

Fit-out contractor Overbury has launched an internal app to help its team identify lights and other office equipment which can be reused across the company’s sites in the UK.

The Reuse Market Place is designed to enable accessible and easy sharing of materials and supplies such as luminaires, ceilings, raised access floors and furniture.

The company says the app is formalising an established but ad hoc process. It will lead to a reduction in embodied carbon and the diversion of material from the waste stream.

It supports is sustainability accreditations by ‘closing the loop’ on material.

The company has just finished a project where it has taken smart-enabled luminaires from a building in Manchester and reinstalled them in another building in Wakefield.

Overbury work closely with Whitecroft Lighting, the original supplier of the Selene luminaires, on the logistics of the operation, which required a period of storage at Whitecroft’s factory.

The incoming tenants didn’t wish to retain the speculative Cat A fit-out, meaning the lights were destined for the waste steam.

‘We all knew that we had to do better with these fittings,’ said Overbury environmental and sustainability manager, James Ivin. The firm got in contact with Tim Bowes from Whitecroft Lighting who organised the careful packaging, removal and re-warranty of the fittings. Most were then re-installed in the building in Wakefield.

‘We’ve still got a number of those fittings in storage at Whitecroft,’ says Ivin, ‘So we’re still exploring opportunities with different developers, different projects, different contracts, as well to see how we get those reused in

other spaces.’

Ivin says manufacturers are starting to join the the company on sustainability journey and exploring reuse.

But the challenges remain: ‘We need to take down the fittings carefully. This takes time and extra cost. We call it ‘conscientious strip-out’.

‘And then you have to find a place to store them. We need a ‘swing space’ to get them out of project A, ready to go into unknown project B. Finding project B can also be very difficult as well. We need to make sure [the lights] work with a look and feel, making sure the number is there. Then there’s timing, which is sometimes based on luck’.